Daytona Rising: Inside the World Center of Racing’s Redevelopment

Projects

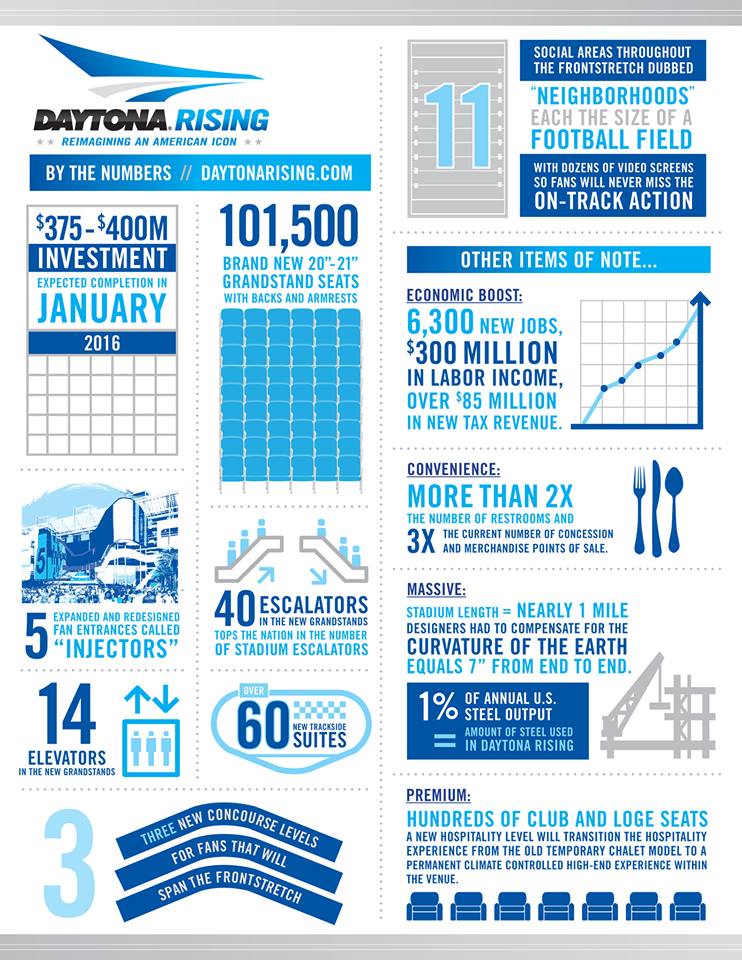

The design-build project consisted of a fronstretch grandstand replacement, which included installing 100,000 wider seats for spectator comfort, new club-level seats, new suites, more restroom areas, and more concession stands. Considered the most prestigious race in NASCAR, the Daytona 500 has been held since 1959 and has officially kicked off the NASCAR Cup season since 1982.

Held at what’s known as “The World Center of Racing,” the Daytona International Speedway is among the largest outdoor stadiums in the nation – and following its latest redevelopment project that concluded in 2016 – the venue got even bigger.

Barton Malow broke ground on the “Daytona Rising” project in 2013 to bring some much-needed improvements to the iconic raceway. The design-build project with ROSSETTI consisted of a fronstretch grandstand replacement, which included installing 100,000 wider seats for spectator comfort, new club-level seats, new suites, more restroom areas, and more concession stands. The project also consisted of building expanded and redesigned “injector” entrance spaces that connect race fans to a series of elevators and escalators to help them get to the various concourse levels more easily.

A game-changer project for Barton Malow, the project required careful coordination, scheduling, and, above all, safety throughout the 30 months of construction. With 16 events and over 1,000,000 fans visiting the site during construction, there was zero room for unsafe acts. In addition to safety barriers, wayfinding signs, and turnstiles to enter the site, we used modularization, another significant tool to minimize disruptions. This included the prefabrication of 88 “houses,” averaging approximately 1,500 SF each. The “houses” contained the stadium’s restrooms, concession stands, first aid rooms, and other operations. Each “house’s” exterior took about eight days to complete off-site and then was brought to the site and set in place. Building off-site made the whole project more efficient and minimized the safety issues at the track.

“We want our team to go home the same way they came into work. During the intense planning for this iconic project, it was determined that we needed to protect our team with a portable railing system for roughly five miles of leading edge on all the grandstand levels,” recalls Safety Manager Rome Overmyer. “Another important part of our planning was the ‘Race Ready’ provisions it was going to take to allow Daytona International Speedway (DIS) to continue to operate events during the three-year phased construction project. Each event provided different challenges to get 100,000 plus spectators through our massive construction project safely. City officials, DIS management, and Barton Malow would conduct walk-throughs looking for any potential hazards before the events occurred.”

Barton Malow’s relationship with the International Speedway Corporation started in the early 2000s, thanks in part to a partnership born out of the Richmond, Virginia, office.

An aerial shot of the Daytona International Speedway

A local Richmond firm was selected to perform a small renovation and expansion for the Torque Club at the Richmond International Speedway. This firm partnered with Barton Malow to carry out the job. Not only was this job a success, but it helped foster relationships that would eventually lead to the Daytona International Speedway project.

The project consisted of installing 100,000 wider seats, new club-level seating, new suites, twice as many restrooms, and three times the concession stands of before.

Even with a great relationship, winning the project was far from simple. The team had to prepare for a grueling three-hour interview with the owner. But in the end, all the preparation and planning paid off.

“The feedback we got from the International Speedway Corporation afterward was that we were so well prepared, so orchestrated, very well delivered,” remembers Barton Malow Vice President Len Moser. “Everything just went perfectly in terms of the delivery of the message that we blew them away. It was a unanimous vote amongst the selection committee.”

One of the most significant projects built in Barton Malow’s 100-year history, the Daytona Rising project has won over 22 awards and accolades, including Sports Business Journal’s 2016 Sports Facility of the Year and Associated Builders and Contractors’ Project of the Year. The project also resulted in more than 700 million media impressions during its three-year construction.

“Today, I stand in front of this mile-long project and say that I am proud of what has been accomplished and what our fans and visitors get to experience at every event,” Derek Muldowney, Vice President of the International Speedway Corporation and President of ISC Design & Development, said following project completion. “The team took our vision back in 2012 and turned it into the first motorsports stadium in the world, and a facility that will be sustainable for years to come.”

For the Win: Daytona International Speedway

When selected for a small project for Richmond Raceway in 2009, Barton Malow got its foot in the door with International Speedway Corporation, now part of NASCAR. Three years later, in 2012, Barton Malow got to compete for the Daytona Rising project, renovating and revitalizing the Frontstretch Grandstand of one of America’s most iconic racetracks. Replacing the grandstand, installing 100,000 wider seats, adding club-level seating and suites, and more made this project a massive undertaking. Allowing race events to continue during the 30-month construction schedule made the task even more daunting.

“I think the risk factor for us was very evident right out of the gate,” says Barton Malow Vice President Len Moser.

The Game Changer Mentality

For Len and the rest of the Barton Malow team, the opportunity to work with NASCAR could change the geographic and market footprint of the company. According to Len, the team knew the importance of rallying the whole company to not just win the project but to deliver it on time and under complex circumstances.

“We even created a specific room in our corporate headquarters in Southfield that was our war room for the project,” he recalls. “We would meet there, and pin-up renderings, drawings, logistics playbooks, and schedules on the walls, basically immersing ourselves in the project to really understand what it was going to take to win it, but more importantly, how we're going to execute it."

Getting to the Finish Line

A big part of the presentation was a physical model of the proposed concept, allowing the selection committee to add and remove pieces of the model to see how each area could be renovated while events were continuing throughout the year.

“We were at the beach, and I had my phone nearby just waiting for any news on the project,” he recalls. “The Vice President of our Florida office at the time received a call from the leader of the group we interviewed with at International Speedway Corporation. I was on the beach in St. Croix when I received the call that they were rewarding the project to Barton Malow.”

Since then, NASCAR has driven more opportunities to Barton Malow, much in part due to the relationships built during the once-in-a-lifetime, game-changing opportunity to get the checkered flag at Daytona.