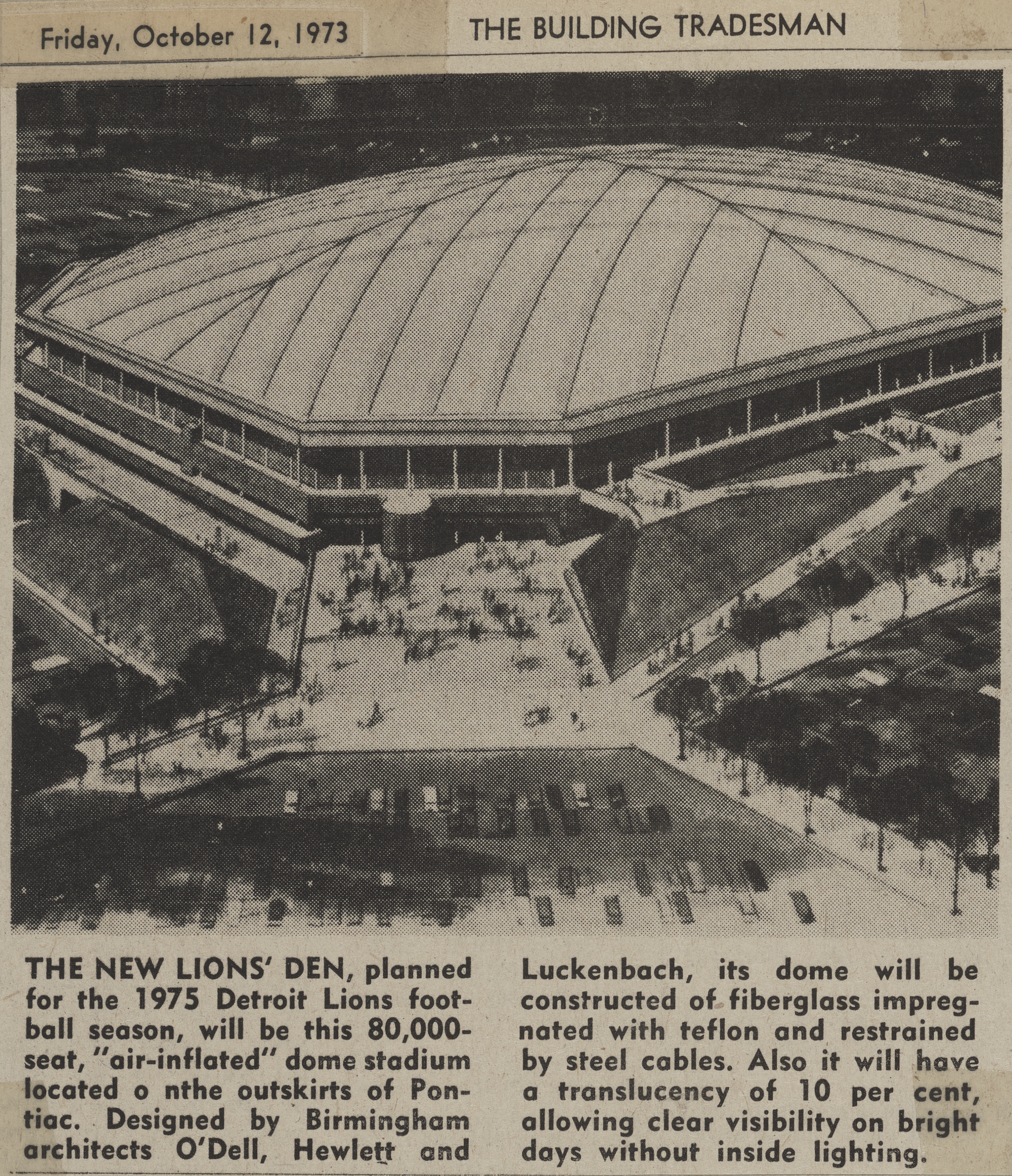

The Pontiac Silverdome: An Engineering Marvel of Its Time

Projects

When many people think of the Pontiac Silverdome, they associate it with the home of the Detroit Lions from 1975 through 2001. But beyond serving as the home field of an NFL football team, the Silverdome is arguably just as well known for the attendance records it set at the time for some of the biggest acts in entertainment, underscoring the sheer size and scale of the development.

Once the largest stadium in the NFL with a football capacity of up to 80,600, the Pontiac Silverdome hosted everything from WrestleMania III to mass with then-Pope John Paul II, musical acts ranging from Bruce Springsteen to Elvis Presley, and special events like the 1994 FIFA World Cup. It also served as the home court of the Detroit Pistons from 1978-1988.

But beyond attendance records and the number of events it hosted, the Silverdome was truly a first-of-its-kind facility. Of particular note was the inflated concave roof, which was supported by air pressure.

A First-of-its-Kind Roof

“Our initial contract was $40-45 million to build an open-air stadium,” remembers Chief Community Officer Ben Maibach III. “Just as we were breaking ground, they decided to put a roof on it.”

At the time, the country’s largest fabric roof air structure was about 1 acre in size over a tennis facility in Iowa. The Silverdome required a fabric roof about 12 acres in size in what would become the largest domed stadium project in North America.

“There had never been anything of that nature ever done,” says Ben.

With the use of helicopters, the roof was installed and inflated to essentially resemble a 200-ton tent. It was held together and restrained by 18 crisscrossing suspension cables ranging in size from 550 to 750 feet and weighing up to 15,000 pounds. The roof was inflated using ten 75-hp fans and 15 100-hp fans. Doors installed on the facility were pressure balanced.

Pontiac Silverdome Aerial View - 1976

Overall, the project was successful, completed on time (23 months) and within budget – a feat that was particularly remarkable during a period of inflation when many comparable projects experienced delays and cost overruns. It also helped Barton Malow earn subsequent work building the Metrodome in Minneapolis and the Georgia Dome in Atlanta, each featuring inflated roofs.

Just as there are traditionally ceremonies for groundbreakings, steel topping outs, and ribbon cuttings, the Barton Malow teams also held “roof inflation ceremonies” on the Silverdome, Metrodome, and Georgia Dome projects.

Built So Good, They Couldn’t Bring it Down

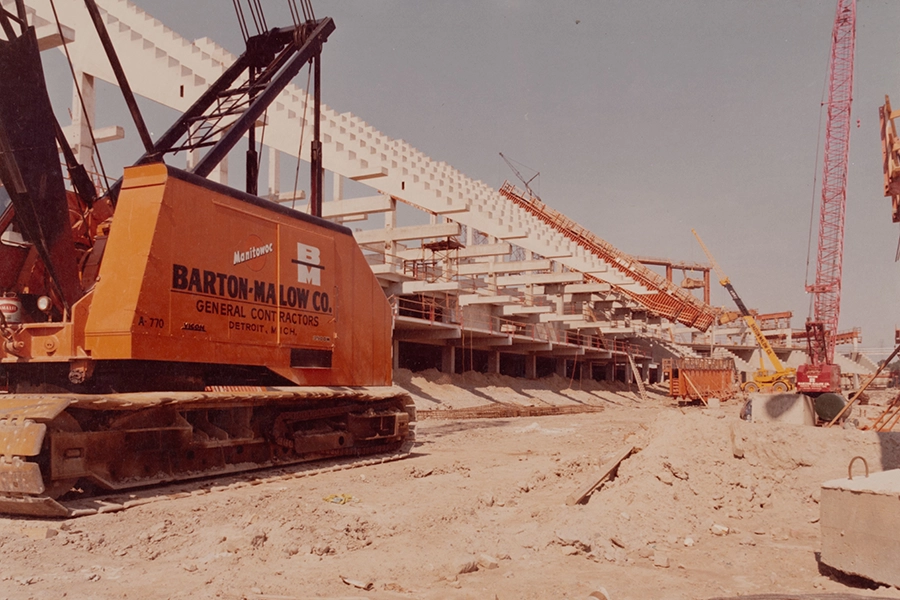

The Silverdome roof wasn’t the only thing notable about the project. At the time, it also happened to be one of the biggest jobs that Barton Malow had taken on. About 1.5 million cubic yards of dirt were moved for construction. More than 1,700 tons of structural steel was set and 52,000 cubic yards of concrete was poured. It was built by more than 2,500 trades workers, representing 17 trades – without any work stoppages or overtime.

Barton Malow COO Chuck Binkowski remembers visiting the jobsite as a teenager with his father, Bruno, a career tradesman who spent more than 40 years with Barton Malow.

“It was the biggest concrete job he had ever done,” recalls Chuck.

In building it, the upper level of the stadium was built first. Then, the field was dug out, and work on the lower bowl and at the field level commenced.

Jon Csont spent 47 years with Barton Malow and worked as a carpenter on the project. It was the first major project he worked on.

"That was a project you wanted to work on; you wanted to be part of it. It was a job you woke up always wanting to go to every day."

Jon Csont

Carpenter on the Pontiac Silverdome

The Lions moved back downtown to Ford Field in 2001, and though the Silverdome continued to host concerts and special events, years of failed attempts at redevelopment and repurposing eventually led to its demolition in December 2017. But the initial implosion didn’t exactly go as planned and the building stayed standing – at least until the next day when they could attempt it again.

The official word was a wiring error prevented eight explosives from going off around the perimeter of the facility. Others joked that it was because the facility was built too well.

“I got a bunch of texts when they went to implode it,” remembers Chuck. “All the guys that knew my dad, they were saying, ‘Bruno really built that thing.’”

Jon recalls, “It was built to last. It wasn’t ready to die. I just had a feeling it wasn’t going to die that easy – just the way the thing was constructed.”

Construction worker sitting in the first 20 seats installed to test for the most efficient installation method at the Pontiac Silverdome - 1974

Awards and Accolades

The feat that was the Pontiac Silverdome wasn’t lost on the construction industry. Its honors included the Associated General Contractors of America (AGC) “Build America” Award and the National Society of Professional Engineers also cited it as one of the “10 Outstanding Engineering Achievements” in 1975.

Engineering News-Record magazine hailed the project as “one of the great design and construction achievements of our time.”

More on the Silverdome

Pontiac Silverdome groundbreaking, Pontiac Mayor Robert F. Jackson, Detroit Lions owner William Clay Ford, and Pontiac Stadium Authority's Harold A. Cousins shown left to right with shovels - 1973