Barton Malow and General Motors: A Partnership Driving Innovation

Projects

Barton Malow and General Motors (GM) have had a strong, enduring partnership since 1930. Over the years, we collaborated on significant projects that revolutionized our businesses.

Some of our most notable and impactful projects with the automatic took place in the ’70s and ’80s. Barton Malow’s partnership with GM was solidified and reached new heights when we became the go-to contractor for upkeep and enhancements in GM’s existing Cadillac Motor Clark Street plants, which blossomed into maintenance contracts for plants throughout the state.

After meeting with GM to present the concept of Construction Management, we were able to negotiate two office buildings in the Warren Technical Center to showcase our capacity for the new project delivery approach. These projects served as the launch pad for Barton Malow Construction Management and Program Management Services.

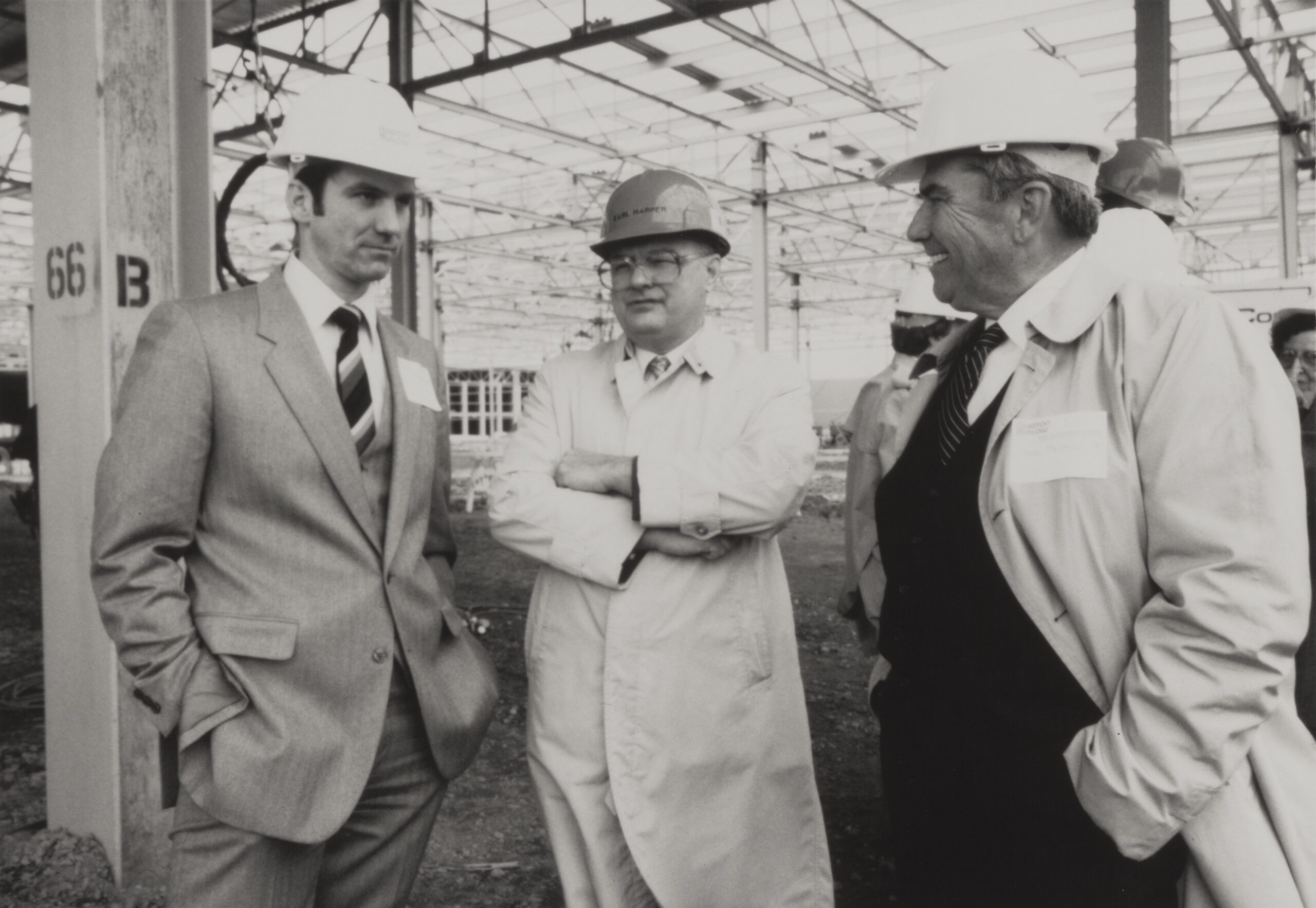

General Motors Assembly Division World Headquarters

Furthering Our Reach

The GM Assembly Division projects at locations in Lake Orion and Hamtramck, Michigan; Wentzville, Missouri; and Fort Wayne, Indiana, were pivotal for Barton Malow. These four projects served as the launch pad for Barton Malow Construction Management and Program Management Services.

“Back in the ‘80s, teaming up with General Motors was a game-changer for Barton Malow,” says Barton Malow Chief Community Officer Ben Maibach III. “It wasn’t just about local projects anymore. We were placed onto the national stage as trusted construction and program managers.”

The impact of these projects extended beyond Barton Malow, revolutionizing how GM carried out its work as well.

"It wasn’t just about local projects anymore. We were placed onto the national stage as trusted construction and program managers."

Ben Maibach III

Chief Community Officer

Importance of Relationships, Integrity, and Trust

Trust and integrity have been pivotal in the partnership between Barton Malow and GM. Like other major automakers, GM was encountering challenges such as competitive construction costs per square foot and budget and schedule constraints. When GM decided to construct a new engine plant in Flint, Michigan, it approached Barton Malow to explore the possibility of expediting the construction timeline based on the successful track record of previous GM Assembly Division projects.

“When it comes to our partnership with GM, it’s all about integrity and reliability,” says now-retired Barton Malow executive Bruce Rysztak. “We’ve reshaped how projects get done, bringing in collaboration and flexibility that not only benefit us but also set new standards in the industry.”

Collaboration and Leaning-in

The Flint V6 Powertrain project in 2004 was another true game-changer, allowing Barton Malow to redefine project delivery rules and introduce collaborative approaches, self-perform work, and flexible strategies.

Due to the urgent and critical timing of the Flint V6 Powertrain project, Barton Malow once more altered the approach to project delivery. We moved away from conventional methods and embraced more collaborative, adaptable, and self-performance approaches. By taking on the work ourselves, we focused on forming partnerships, integrating schedules, and sharing risks and rewards to facilitate collaborative decision-making with GM and its partners. This project laid the groundwork for future successes and led to changes in GM’s construction operations structure that fostered a renewed partnership. Together, we understood the value of identifying issues early and working together to find solutions.

Formalizing Partnering, Evolution, and Legacy

After completing the Flint project, Barton Malow was also chosen for projects in Toledo, Ohio, and an Assembly Complex in central Mexico. Once again, we implemented a collaborative approach to both the design and construction processes. This successful partnership with GM has led to significant projects and growth opportunities for Barton Malow across North America.

Building on the success of earlier projects, both GM and Barton Malow have recognized the value of addressing challenges and finding solutions collaboratively. This led to the first Integrated Project Delivery (IPD) contract between GM and Barton Malow. The agreement formalized the partnership processes, particularly within the M5 Productivity Improvement Program, four 1 million-SF Body Shop expansions in Fort Wayne, Indiana; Arlington, Texas; Flint, Michigan; and Silao, Mexico. The project teams emphasized integrated scheduling and shared risk and return.

Legacy projects such as M5 have further cemented Barton Malow’s evolution and success in our relationship with GM.

Concrete Heroes: The Inside Story of the MegaSlab

Listen to the “Concrete Heros: The Inside Story of the MegaSlab” episode of Said Differently, a Barton Malow Podcast, for more insight from team members who played a major role in the planning and execution of the 256,100 SF MegaSlab that was a part of the Arlington, TX expansion project.

Legacy projects such as M5 have further cemented Barton Malow’s evolution and success in our relationship with GM.

Ultium Cells in Spring Hill, Tennessee

EMBARKING ON AN ELECTRIFIED FUTURE TOGETHER

As the world gradually transitions to electric vehicles (EVs), Barton Malow continues to play a pivotal role in this shift by constructing state-of-the-art battery manufacturing facilities. Ultium Cells, a joint venture between General Motors and LG Energy Solution, is on its third facility to help GM in its goal of assembling more than one million EVs by mid-decade.

Warren, Ohio

As the first of three Ultium Cells projects, the lithium-ion battery cell manufacturing facility project in northeast Ohio was set to be the single largest project Barton Malow had ever executed at the time and act as the company’s entrance into the EV market.

When project teams began mobilizing in March 2020, no one knew the extent of the challenges that would occur as the COVID-19 pandemic started. As construction continued through 2020, labor and material shortages and price escalations threatened the schedule and budget for the project, as well as the two additional Ultium Cells projects that were in their early planning stages.

Located on 156 acres, Ultium Cells in Ohio spans 2.8 million SF, produces over 40 gigawatt hours of annual capacity, and created over 1,500 new high-tech jobs. Barton Malow Company provided construction services through an IPD approach and self-performed layout, civil, concrete/resteel, steel erection, and interior finishes (metal studs, drywall, doors, and hardware).

“We were approached in November, and after reviewing another plant in December, we kicked off the IPD and started moving dirt in March. It was incredible how fast our collaborative teams came together,” said Alan Blanchette, Senior Director of Project Delivery at Barton Malow Company.

Spring Hill, Tennessee

Down south in Spring Hill, Tennessee, plans were announced for the second Ultium Cells facility in April 2021 where progress is well underway and nearing completion in the spring of this year.

The state-of-the-art plant is scheduled to begin production later this year and will employ 1,700 people in new high-tech jobs to support the production of GM’s Ultium Platform-based EVs, including the Cadillac LYRIQ.

In true Barton Malow fashion, the project teams haven’t only built up the project itself but the surrounding communities, too. It has sponsored several community organizations, including the Nashville Firefighters Association (IAFF Local 140), the High Hopes Development Center, the local VFW, the Boys & Girls Clubs of Middle Tennessee, and more.

Lansing, Michigan

The latest addition to the Ultium Cells portfolio in Lansing, Michigan, was announced in January 2022, with groundbreaking in September of the same year. In January 2024, the project celebrated 2 million work hours.

When finished, the facility will be 2.8 million SF, have a cell operational capacity of 41 GWh, and, by the end of the 2025, employ more than 1,700 people in new high-tech jobs. The facility is scheduled to begin production in Quarter 4 of 2024. Upon completion, the project will cover an area larger than 46 football fields.

Once all three facilities are fully operational, the plants will supply battery cells to various GM facilities throughout North America and will use the most advanced and efficient battery cell manufacturing processes. The plants will be extremely flexible and adapt to ongoing advances in technology and materials. Barton Malow continues to be a trusted partner of GM as it embarks on the EV market and achieves its goals of a sustainable future.

“In every job where Barton Malow self-performs, including Ultium Cells, we’re the first ones on the job moving dirt and last ones there putting on the doorknob closing the door behind us,” Alan says. “We have a lot of pride in our self-perform work, and it helps us drive safety, schedule, and productivity.”

As the first facility to pave the way for Barton Malow’s entrance into the EV market, Ultium Cells in Warren, Ohio achieved incredible success and recognition after completion in late 2022. The project received an Award of Merit in the Energy/Industrial category from ENR Midwest’s 2023 ‘Best Projects,’ which honors projects that represent outstanding quality of work. It earned the TAUC 2023 Joseph R. La Rocca Union Project of the Year Award for its exceptional work performed under labor-management cooperation, specifically pertaining to collaboration and teamwork, quality and craftsmanship, execution, and safety, and was among the National Association of Women in Construction’s 2023 Excellence Awards.

Most recently, the project was honored with the Lean Construction Institute’s first annual Engineering Design Award for delivering excellence in fit-for-use and engineering design while advancing the industry through collaborative Lean Project Delivery.

Ultium in Lansing, Michigan